A-Z of tiling terms

Abrasion Resistance

The degree to which a floor tile’s surface will withstand friction (the wear of foot traffic). Resistance is determined by abrasion tests. (AS 4459-7) classifies tiles from Group I (suitable for light residential traffic) to Group V (suitable for commercial traffic)

Abrasive Hardness

Abrasive hardness (Ha) is an industry method to determine the ability of a particular tile’s resistance to wearing from abrasive substances. This can be an important consideration when selecting tiles or stone for flooring in a commercial setting. It is generally recommended that products being considered for flooring have a Ha of 10 or more, or even 12 or more in heavy traffic areas. It is also recommended that if different types and varieties of tiles or stone are used together that the Ha ratings should not be too far apart from each other. This will ensure a uniform appearance when the stone begins to show wear. The dirt and grit that is tracked into buildings has a hardness range from 3 to 7, and foot traffic tends to have an abrasion factor of 120 to 220 grit, equivalent to sandpaper at the same grits.

Absorption

Absorbency is an important determining factor in tile's sensitivity to stain. The size of the pores, their orientation, how well they are networked and the type of finish the stone has are important contributing factors to a stone’s overall absorbency. In relation to cleaning ability this factor is more important than how porous a stone or tile is. Honed and textured surfaces are more susceptible to soiling and staining due to the fact that there are more open pores at the surface than a highly polished finish. The polishing process has a tendency to close off pores leaving fewer pores exposed, resulting in a low absorbent surface. However, some varieties of stone have large pores and capillary structures and even when these stones are polished they still remain very absorbent.

Accelerated Wear Test (AWT)

(See Sustainable Slip Resistance)

Acid Resistance

(See Chemical resistance)

Acid Wash

A treatment to the face of a stone to achieve a texture or finish that is distressed. Chemical treatments are more effective when applied to calcareous stones than to siliceous stone types. Recently, the use of acid and other types of chemical has lessened due to environmental and disposal concerns. Chemical processes have been replaced by mechanical methods for the texturing of the stone face.

Adhered

Secured and supported by adhesion of an approved bonding material over an approved backing; is used in reference to stone veneer.

Adhesives

(See Bonding Material)

Agglomerated stone

A man made product composed of crushed stone combined with resin

Aggregate

A mixture of diverse minerals or other loose materials in a cementing agent.

Alkali Resistance

(See Chemical resistance)

Anchor

A metal fastener used for securing dimension stone to a structure. Anchor types of stonework include those made of flat stock (strap, cramps, dovetails, dowel, strap dowel and two way anchors and round stock (rod cramp, rod anchor, eyebolt, and dowel, flat-hood wall tile and dowel, dowel and wire toggle bolts.

Anchorage

The means by which slabs are attached to a self supporting structure.

Antique finish

A finish that replicates rusticated or distressed textures. Produced through mechanical or chemical means to stimulate the naturally occurring effects of the age process.

Anti-Slip Tiles

(See Slip resistant tiles)

Apparent Joint

Decorative feature that simulates grout lines or joints on a single tile, so that a large tile, for example, may appear to be four smaller tiles.

Apron

A trim piece under a projecting stone top, stool etc.

Arriss

An edge or angle where two surfaces meet for example mouldings and raised edge.

Backsplash

See splashback

Basalt

A dense-textured (aphanitic) igneous rock relatively high in iron and magnesia minerals and relatively low in silica, generally dark grey to black and feldspathic; a general term in contradistinction to felsite, a light-coloured feldspathic and highly siliceous rock of similar texture and origin

Bas Relief

Decorative technique in which design elements are sculpted or carved to be raised slightly from background.

Bed (Tile)

Layer of mortar or other adhesive that covers the surface to be tiled and onto which the tiles are set.

Bevel

A sloped surface contiguous with a vertical or horizontal surface

Bicottura

Literally ‘two firings’, referring to the separate firing of the clay body and the glaze. Bicottura glazes are not as scratch resistant and are now only used on walls.

Blasted Finish

A matte-textured surface finish with no gloss, finished by application of a steady flow of blasting medium under pressure.

Bluestone

Bluestone is the common name for any blue-grey, fine-grained igneous rock, typically of basaltic composition. The term is not a geological term but a popular name given to several different stones from different parts of the world. Bluestone in Australia refers to a basalt or olivine basalt from the extensive basalt plains of western Victoria. Basalt is of igneous origin and is the most common stone type in the world. Victorian blue stone has been used extensively throughout Australia for paving kerbing and cladding.

Biscuit or Bisque

(See Body of Tile)

Body (of tile)

The structural portion of a ceramic article, as distinct from the glaze, or the material or mixture from which the item is made.

Book match pattern

A layout in pairs of all stone elements to confirm that the design matches.

Bonding Material

Any of the mortars or adhesives used to install ceramic tile. Choice of bonding material is determined by the selection of tile and requirements of area to be tiled. Using the correct bonding material is essential. Problematic jobs are almost inevitably a laying problem, and the most common is due to the use of the wrong bonding material. We recommend Mapei Australia (simply click on the link to view their range of products).www.mapei.com.au

Border Tiles

(See Trim tiles)

Breaking Strength

The ability of a material to resist breaking or rupture from a tension force.

Brushed finish

Obtained by brushing a stone with a coarse rotary type wire brush also referred to as satin finish.

Bullnose Tiles

Trim tiles featuring one rounded edge used to finish wall installations or turn outside corners. Also Double-Bullnose tiles with two rounded edges.

Bush hammering

A mechanical process which produces textured surfaces that vary from subtle to rough.

Buttering, also Back-buttering

Applying bonding material directly to the back of a tile to provide additional coverage in the setting bed. Technique usually applied to large (200x200mm and up) tiles.

Calibration

The first step in the finishing process of a stone tile. Coarse abrasive pads are mounted to the bottom of rotating wheels that under extreme pressure and rotation speed are applied to the face of the stone. This process grinds the stone to a uniform and consistent thickness of+1mm tolerance, which is crucial for the installation of tile in a thin-set application. Calibration process is not possible sawn-back or ground back techniques are applied to these types of stone and are correctly called gauging which is not a precision-oriented as calibration.

Ceramic Tiles

“Ceramic” or non-porcelain tiles are generally made from red or white clay fired in a kiln. They are almost always finished with a durable glaze which carries the colour and pattern. These tiles are used in both wall tile and floor tile applications, are softer and easier to cut than porcelain, and usually carry a PEI 0 to 3 rating. Non-porcelain ceramic tiles are usually suitable for very light to moderate traffic and generally have a relatively high water absorption rating making them less frost resistant and they are more prone to wear and chipping than porcelain tiles.

Chemical Resistance

The ability of a tile surface to withstand damage from chemicals, acids, alkalis and swimming pool salts.

Chiselled edge

A process of mechanically chipping the tile edge thus giving the stone a rustic aged appearance.

Cladding

Non-load-bearing stone veneer used as the facing material in exterior wall construction.

Clay

Natural earthen material, plastic when wet, that is the basic raw material of ceramic tiles.

Cleft finish

Rough-surfaced stones such as slates that are cleaved or separated along a natural seam are referred to as natural cleft. These types of stone were formed as a result of metamorphic foliation.

Clinker Tiles

Natural clay tile, generally extruded, with properties similar to red stoneware. (also Klinker)

Cobblestone

A dimension stone large enough for use in paving. Term commonly used it describe paving blocks usually granite and generally cut it rectangular shapes.

Coefficient of friction

Measurement, either dynamic or static, used to determine different aspects of slippage on a tiled plane. Measures include wet and dry conditions, speed of subject, required force to move subject, and critical angle of tiled surface. Area use and maintenance directly affect a tile's coefficient of friction.

Colour Permanence

While most coloured materials will be altered by long exposure to light, colours in ceramic tiles are unaffected and will not change or fade from exposure.

Control joint

A joint that allows for dimensional changes of different parts of a structure due shrinkage or expansion variations in temperature or other causes. Its purpose is to prevent development of high stresses in the structure.

Coping

A flat tile or stone used as a cap on freestanding walls.

Corundum

An abrasive or grit added to a tile glaze in order to increase tile slip-resistance.

Cotto

(See Terracotta)

Cove Tiles

Cove trim tiles with rounded top edge, used to finish tile installation as baseboard, backsplash, etc.

Crackle Glaze

Special glaze featuring fine-line 'cracks' for antique effect.

Crazing

A fine, hair-line cracking which sometimes appears on the glazed face of a tile. Usually caused by tensile stress between tile body and glaze. May be intentionally produced for artistic effect.

Curing

Process allowing new tile installation to set.

Decal

Transfer design used to decorate ceramic tiles.

Decorated Tile

Ceramic tiles that have been embellished by means of hand painting, silk screening, decals or other techniques.

Dimensional Standards for Ceramic Tiles

First quality ceramic tiles must meet the standards of their class for length, width, thickness, straightness of sides, rectangularity, and surface flatness. (AS4662)

Diamond sawed

Finish produced by sawing with a diamond toothed circular or gang saw.

Dimension stone

A natural building stone that has been cut and finished to specifications.

Double-Fired Tiles

Glazed tiles produced by an initial firing of the shaped tile body and then a second firing once the glaze or decoration has been applied.

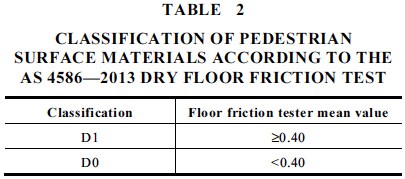

Dry Floor Friction (FFT)

The dry floor friction test method employs a simple apparatus that drags a small slider across a dry pedestrian surface, giving a continuous reading of the apparent coefficient of friction of the specimen. This is assessed by determining the dynamic friction between the specimen and a slider moving at a constant speed of 1 Å}0.1 m/min across the surface, by measuring the ratio of the tangential force to the vertical load.

This test provides a quick and simple assessment of the slip resistance of dry surfaces; however, the results of the dry floor friction test are not appropriate for surfaces in the wet condition. If a pedestrian surface is liable to become wet, and remain wet and unattended for any significant length of time, the wet pendulum test method, wet-barefoot inclining platform test method or the oil-wet inclining platform test method (as appropriate) should be used.

A new nomenclature was also introduced in AS 4586—2013 (see Table 2) for the dry floor friction test, replacing classifications F and G with D1 and D0.

The above information should not be relied upon without reference to Australian Standards SA HB 198:2014. Information and tables sourced from Australian Standards SA HB 198:2014.

Dry-Pressed Tiles

(See Dust-pressed)

Dust-Pressed Tiles

Tiles formed by the dust pressed method in which the finely milled raw materials are shaped in moulds at high pressure before firing. (See also Extruded tiles)

Efflorescence

Crystalline deposit that sometimes appears on the surface of grout joints or unglazed tiles as a whitish powder or crust, caused by moisture reacting with impurities in the mortar.

Epoxy

Resin material used in mortars and grouts for thin-set tile installations.

Expansion Joint

Separation provided between adjoining parts of a structure to allow movement at stress points to prevent uncontrolled cracking.

Extruded Tiles

Tiles formed by the extrusion process wherein the still malleable or plastic raw material is forced through a mould and then cut into shape before firing.

Single extruded tiles are produced in a long slab which is then cut to shape.

Double-extruded tiles, also known as split tiles, are produced in a column that must be split before tiles are cut. (See also Dust-pressed tiles)

Finishes

Textural or visual characteristics of a tile surface. For glazed tile this may be high gloss, satin or matt. Generally for porcelain tiles, finish can be natural, polished, semi-polished, honed, lapped. Other finishes mimicking stone such as bush hammered are also available. Other effects include raised, embossed, dimpled, etched, scored, ribbed, etc.

Fire Resistance

In many instances ceramic tile suppliers have been requested to provide fire ratings for ceramic tiles and the like. Fire ratings are required by the Building Code of Australia (BCA) to ensure that if a building is on fire, that the material does not significantly increase the spread or intensity of a fire. The fire ratings are generally required for new building work or major refurbishments as part of council requirements.

As tiles are fired at over 1000 degrees Celsius there are certain provisions that are in place due to the nature and production process of tiles.

The cost of conducting fire ratings for every project are extreme, as such the NSW amendment of the Building Code of Australia 1.10 states that the requirements do not apply if it is ceramic tile or the like and are considered ‘deemed to satisfy' under the provision of the Building Code of Australia.

Firing

Final step of tile manufacturing process when raw material is "baked" at high temperature (up to 1250°C for impervious tiles) to harden tile body and glaze, if any.

Fissure

A hairline opening in the face of stone demonstrating stones natural characteristics; a lineal or non directional void in the face and crystalline structure of stone that typically is very thin and irregular.

Flamed finish

A surface finish applied by intense heat. Flaming – also termed ‘exfoliated finish’ also know as thermal flamed.

Floor Tiles

Glazed or unglazed tiles of sufficient strength, impact and abrasion resistance to withstand the weight and wear of foot traffic.

Frost Resistance

Ability of certain ceramic tiles to withstand freeze/thaw conditions with minimal effect. Frost resistance of ceramic tile is dependent on the tile’s porosity and water absorption levels.

Fully Vitrified Stoneware

(See Porcelain Stoneware)

Glass Mosaic

Mosaic tiles composed of glass, rather than ceramic, material; mosaic tiles coated with a layer of coloured or transparent glass.

Glaze

Glassy coating fired on a ceramic tile.

Glazed Tiles

Ceramic tiles with an opaque or transparent coating that has been fused to the tile body by firing, creating a smooth, impermeable surface that may also be highly decorated.

Glazed Porcelain

Currently the most popular type of indoor floor tile. The tile is made from porcelain clays but glazed for aesthetic effect. Glazed porcelain tiles are dense, strong and may require cutting with a wet saw.

Grain

1. The main direction of the mineral composition and arrangement in stone; it is also the easiest direction of cleavage.

2. A very small particle of rock, such as a sand grain.

Granite

Coarse-grained igneous rock of even texture and colour, composed chiefly of quartz and feldspars. It usually contains small quantities of mica or hornblende, and minor accessory minerals may be present. Depending on the feldspar present, granite may be pink, dark gray, or light gray. It is commonly believed to have solidified from molten rock (called magma) under pressure. However, some granites show no contacts with surrounding wall rock, but instead gradually grade into metamorphic rock. Others show relic features found in sediments. This evidence suggests that some granites are not igneous in origin, but metamorphic. Some granites are the oldest known rocks on earth; others were formed during younger geologic periods. Crystallized at depth, granite masses are exposed at the earth's surface by crustal movement or by the erosion of overlying rocks. Very coarse-grained granite, called pegmatite, may contain minerals and gemstones of economic value.

Grout

Grout is the material that is applied between tiles to fill in the spaces and give strength to the tile work. For tiles that are close together (1-2mm, or about the thickness of a coin), non-sanded grout is used. For tiles wider apart than this, sanded grout is used. Grout is applied after the tile is laid down on its bed of mortar. The grout is squeezed into the spaces with a tile float, and then wiped clean away with the same tile float and with a wet sponge. Grout is more than a utilitarian material. Grout of different tints, textures, and colours can be used to give your tile work completely different looks.

Selecting the correct grout is just as important as selecting the correct adhesive. We recommend Mapei Australia (simply click on the link to view their range of products). www.mapei.com.au

Grout joint

Space left between tiles to be filled with grout. This space may be extremely narrow or wider depending on the required installation and/or its aesthetics.

Hardness/Density

Hardness and density in relation to stone surfaces is a measure of the resistance of any substance that will scratch or abrade its surface. The hardness factor is a physical property of the tile’s physical composition, density and porosity. Different minerals and stones have different degrees of hardness and density and therefore have different degrees of resistance to scratching and abrasion.

Refer to MOH scale of hardness for measurements of hardness and density.

Honed Finish

A satin- smooth surface finish with little or no gloss, recommended for commercial floors.

Hygiene

The face of ceramic tiles will not retain liquids, absorb fumes, odors, or smoke. This allows for good hygiene. Tiles are suited for any environment where hygiene is essential.

Impact Resistance

Ability of ceramic tile to resist breakage - either throughout the body or as surface chipping - as the result of a heavy blow. In general, ceramic tile is not a resilient material, and care should be taken to avoid dropping heavy or sharp objects on its surface. Glazed tiles are more susceptible to surface chipping than unglazed tiles.

Impervious Stoneware Tiles

(See Porcelain Stoneware)

Impregnation

Applying a chemical containing stain inhibitors that penetrates below the surface of the stone.

Inserts

Small, sometimes decorative tiles used in combination with larger or plain tiles to create patterns. Small square inserts are known as insets.

Installation

The process of bonding tiles to the intended surface; the finished tiled surface (also known as tile laying or tile fixing).

Installation Bed

The components of a tile installation applied to the subsurface, including reinforcing or protective backing, bonding materials, tile and grout.

Joint

See particular type of joint, i.e. expansion, grout, isolation, mortar.

Jolly Tiles

Trim tiles mitred along one or two edges, used in corner and countertop installations. Also called angled (45°) tiles.

Klinker

(See Clinker)

Lamination

The gluing of two pieces of stone together to produce an edge that can be shaped to create an aesthetic appearance for countertops.

Limestone

A sedimentary rock composed principally of calcite or dolomite or a combination of the two. Recrystallised limestone, compact microcrystalline limestone and travertine that are capable of taking a polish, are also included in the category 'commercial marble' and may be sold as either limestone or marble.

Linear Thermal Expansion

The change in the dimensions of a given material as a result of changes in temperature.

Lippage

In finished installation, the condition where one edge of a tile is higher than an adjacent tile. May be unavoidable even for tiles that are within the tolerances of dimensional standards.

Listello

Narrow decorative border tile, often designed to compliment a range of field tiles.

Luster

An iridescent decorative surface appearance on glazes, usually produced by the application of a very thin metal film, such as gold, silver, platinum or copper, over the coating surface.

Marble

Metamorphic rock composed wholly or in large part of calcite or dolomite crystals, the crystalline texture being the result of metamorphism of limestone by heat and pressure. The term marble is loosely applied to any limestone or dolomite that takes a good polish and is otherwise suitable as a building stone or ornamental stone. Marbles range in colour from snow-white to gray and black, many varieties being some shade of red, yellow, pink, green, or buff; the colours, which are caused by the presence of impurities (other minerals within the calcium carbonate structure of the marble), are frequently arranged in bands or patches and add to the beauty of the stone when it is cut and polished.

Mechanical Strength

(See Breaking Strength)

Mitered Tiles

(See Jolly Tiles)

Modulus of Rupture

A measure of the cohesive characteristics of the material forming the tile, relating to the degree of compactness and consistency.

Mohs’ Scale

Scale used to express the measure of a material’s hardness from Mohs’ 1 (hardness of talc) to 10 (diamond). The MOH scale of hardness is the method used to measure the ability of one substance to scratch another. The scale ranges in order of increasing relative hardness from 1 (softest) to 10 (hardest).

The objective of the MOH scale is to measure stone’s resistance to hardness. The harder the stone, the more resistant it is to abrasion. When sediment and grit are harder than the surface, they will scratch and harm the stone. Exterior sediment that is tracked into buildings measures between 3.0 - 7.0.

Monocottura

Tiles produced with only one high temperature firing, generally with harder glaze and denser body than wall tiles with moisture absorption below 3 percent.

Monoporosa

Single-fired tiles with higher porosity and water absorption levels than ‘monocottura’ tiles.

Mosaic Tiles

Ceramic mosaic tiles are defined by their size, generally less than 150mm square. Their composition is the same as ceramic tile's. They may be glazed, unglazed, glass or metal.

Mounted Tiles

Tiles assembled into units or sheets by the manufacturer for easier installation. Back and edge mounted tiles are bonded to material (mesh, paper, resin or other) that becomes a part of the installation. Face mounted tiles are bonded to a material that is removed prior to grouting.

Natural Cleft

This generally pertains to stone which are formed in layers in the ground. When such stones are cleaved or separated along a natural seam the remaining surface is referred to as a natural cleft surface.

Natural Stone

A product of nature. A stone such as granite, marble, limestone, slate, travertine or sandstone that is formed by nature and is not artificial or manmade.

Nominal Size

The approximate size of tile's face or thickness used for general purposes.

Onyx

A translucent, generally layered, crypto crystalline calcite with colours in pastel shades, particularly yellow, tan and green.

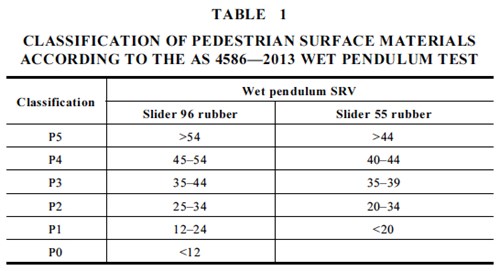

Pendulum Test

The wet pendulum test method is a relatively inexpensive test, and may be performed either in a testing laboratory or on site. The test instrument utilises a pendulum slider making contact with the test surface over a prescribed distance and measures the quantity of resistance to the motion of the pendulum created by the contact. The contact surface of the slider material is prepared to a consistent level of smoothness prior to each group of tests.

Except in the case of internal textile floor coverings, AS 4586—2013 requires that the test be performed under wet conditions, and refers to it as the wet pendulum test method. The terminology ‘wet pendulum test method’ is adopted throughout this Handbook, notwithstanding that internal textile floor coverings are tested dry.

This test provides the greatest flexibility to designers and specifiers, and enables verification of classifications either during manufacture and/or at the completion of construction.

Clause 5 of this Handbook describes the design of pedestrian surfaces using the classifications given in Table 1.

NOTES:

1. The test is known as the ‘wet pendulum test method’, reflecting the fact that it is commonly applied to hard or resilient surfaces to which water is applied. One exception is for internal textile floor coverings, which are tested dry.

2. While either Slider 96 or Slider 55 rubbers may be used depending on the material and its intended application, the test report requires that the rubber that was used be specified.

3. For surfaces that are particularly slippery, it is appropriate to use slider 96 rubber.

The above information should not be relied upon without reference to Australian Standards SA HB 198:2014. Information and tables sourced from Australian Standards SA HB 198:2014.

Permeability

Associated with tile’s porosity is permeability. This is the extent to which the pores and capillary structures are interconnected throughout the stone. These networks, their size, structure and orientation affect the degree and depth to which moisture, vapours and liquids can be absorbed into the interior of the stone or migrate from the substrate by capillary action through the stone. Permeability may be greater in some directions than others based upon the pore size, shape and the distribution of the interconnectedness of the system. Permeability is increased when a stone is highly fractured or the veining material is soft or grainy. A particular variety of stone may be highly permeable (a well defined interconnected network of pores), although its porosity is low (a low percentage of voids).The size and shape of pores and the capillary structure differs in stones and is an important factor in relation to stone decay.

Pointing

The final filing and finishing of mortar joints that have been raked out.

Polished Finish

A glossy surface finish that brings out the full colour and character of the tile or stone.

Porcelain Stoneware

Porcelain stoneware is a tile that is generally made by the dust pressed method from porcelain clays which result in a tile that is dense, impervious, fine grained and smooth, with a sharply formed face. Porcelain tiles usually have a much lower water absorption rate (less than 0.5%) than non-porcelain tiles making them frost resistant or frost-proof. Glazed porcelain tiles are much harder and more wear and damage resistant than non-porcelain ceramic tiles, making them suitable for any application from light traffic to the heaviest residential and light commercial traffic. Full body porcelain tiles carry the colour and pattern through the entire thickness of the tile making them virtually impervious to wear and are suitable for any application from residential to the highest traffic commercial or industrial applications. Porcelain tiles are available in matte, unglazed or a high polished finish.

Porphyry

An igneous rock characterized by distinct and contrasting sizes of coarse and fine-grained crystals. Used as a decorative building stone.

Porosity

Volume of pores relative to volume of tile body and capable of absorbing moisture (and therefore stains). Porosity is by definition the ratio of voids to solids in a tile. It is measured by the amount of water a tile can hold, expressed as a percentage of it’s own weight. The test is carried out by firstly weighing a dry piece of tile, soaking it for 24 hours in water, drying off the surface water, and then weighing the wet piece. The tile’s porosity measurement is the percentage difference between the dry and the wet weights.

Quarry

The location of an operation where a deposit of stone is extracted from the earth from an open pit or underground mine.

Quarry Block

Generally, a rectangular block of rough stone as it comes from a quarry, frequently dressed (scabbed) or wire-sawed for shipment.

Quarry Tiles

Traditional term for single-extruded, natural day tiles with a water absorption level not exceeding 6%

Quartz

A common crystalline stone and a major component of granite.

Quartzite

A hard, metamorphic rock originating as sandstone. Because of its hardness, it sits at about 7 on Mohs' scale. Pure quartzite is usually white to grey. Quartzites often occur in various shades of pink and red due to varying amounts of iron oxide.

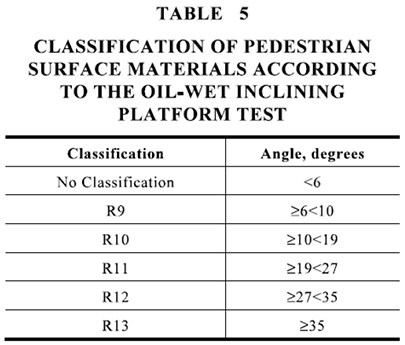

Ramp Test (Oil-Wet Inclining Platform Test Method)

Pedestrian surfacing products, intended for a range of industrial applications, may be classified by the oil-wet inclining platform test method.

Test operators, wearing regulated footwear with highly profiled soles, walk down (forward) and up (backwards) the test surface on the platform using half steps. Prior to conducting each test, the test surface is coated with oil. The operator controls the gradual increase in platform angle.

Similar to the wet-barefoot inclining platform test, the oil-wet inclining platform test classifies surfaces by the specific angle at which slip occurs on the material under controlled laboratory conditions. The measurement and reporting of this angle provides a means of classification, and is not a suggestion that the material is safe to walk on at the slope reported in the test results. Pedestrian surfaces should not be installed at the angles reported in this test.

There are a number of Australian testing laboratories with the necessary testing apparatus, thus enabling the laboratory verification of an overseas classification if required.

Oil-wet inclining platform tests performed overseas may be deemed compatible with AS 4586—2013, in the appropriate circumstances and with appropriate quality assurance.

The above information should not be relied upon without reference to Australian Standards SA HB 198:2014. Information and tables sourced from Australian Standards SA HB 198:2014.

Random Slab

A trimmed slab with a width and length that is not preset but variable within certain limits.

Rectified

Cutting or grinding the edges off a tile allows the dimensions and squareness to be precisely controlled. Typically exhibiting a very square edge, rectified tiles are generally suited for installing without spaces or obvious grout lines between the tiles.

Rustic Finish

Rough or uneven tile surface designed for a non-mechanical, artistic effect.

Sandblasted

See Blasted Finish

Sandstone

Sedimentary rock formed by the cementing together of grains of sand. The usual cementing material in sandstone is calcium carbonate, iron oxides, or silica, and the hardness of sandstone varies according to the character of the cementing material; quartz sandstones cemented with quartz are the hardest. Sandstones are commonly gray, buff, red, or brown although green and some other colours are also found. Green sandstones often contain, in addition to sand and glauconite, fossil shells and iron oxides; those that break apart easily are known as greensands and are sometimes used to replenish depleted potash in soils. Sandstones are widely used in construction and industry.

Sawn Edge

A clean-cut edge generally achieved by cutting with a diamond blade.

Sawn Face

A finish obtained from the process used in producing blocks, slabs, or other units of building stone. It varies in texture from smooth to rough, and is typically named for the type of material used in sawing. E.g. diamond sawn, sand sawn, chat sawn and shot sawn.

Scratch Hardness

(See Mohs' scale)

Screeding

Levelling the mortar bed by dragging a screed across it.

Sealants

There are different types of sealants to give different finishes and a professional should be contacted to ensure the correct product is used to suit the purpose. Penetrating sealants leaves the stone looking natural; while enhancing sealants highlight colours within the stone. Sealants are applied to natural stone, and sometimes unglazed tiles, to help protect the surface from grease spills or staining materials (also known as sealers).

Self-Levelling Compound

Some screeded floors are not entirely flat or smooth. Application of a thin coat of a two-part levelling compound will provide a flat surface, suitable for tiling. These materials will dry rapidly. We recommend Mapei Australia (simply click on the link to view their range of products). www.mapei.com.au

Shade Variation

Many tiles, both glazed and unglazed, are deliberately produced with a wide shade variation to capture the natural beauty of the product. A certain degree of shade variation is inherent in all tiles, stone and mosaics.The manufacturers limit the amount of shade variation within a carton by sorting the tile as it comes off the production line. Also, the shade and run numbers are marked on each carton. To minimize any noticeable shade variations, the installers work out of several cartons simultaneously. In doing so, they are able to blend the tiles together.

Single-Fired Tiles

Glazed tiles produced by the single-firing method in which the raw tile body and the glaze undergo a single pass through the kiln at high temperature. Also known as Monocottura tiles.

Slab

A lengthwise-cut piece sawn or split from a quarry block prior to fabrication.

Slate

Fine-grained rock formed when sedimentary rocks such as shale are metamorphosed by great pressure. Slate splits into perfectly cleaved, broad thin layers; this characteristically regular and planar cleavage is called slaty cleavage. In the formation of slate, pressure causes the flaky minerals within the sedimentary rock, such as mica, clay, and chlorite, to be reoriented; the flat faces of the minerals lie at right angles to the source of the pressure, and the planes of easy cleavage are also at right angles to the source of the pressure. The rock is not necessarily compressed in the same direction as the sedimentary layers were originally laid down, and because the compression crumples and deforms the original sedimentary layers, the planes of slaty cleavage usually cut through the old bedding planes. Slate is intermediate in hardness between mica schists and shale. Its characteristic colour is gray-blue.

Slip Resistant Tiles

Tiles treated to prevent slipping either by adding an abrasive grit to the glaze or texture to the surface such as ribs, studs or orange peel finish. (See Coefficient of Friction)

Slip Resistance of Pedestrian Surfaces

See Slip Resistance page.

Soapstone

A massive variety of talc with a soapy or greasy feel used for hearths, washtubs, table tops, carved ornaments, chemical laboratory counters, etc and know for its stain-proof qualities.

Splashback

Vertical cladding to the wall above countertop.

Split-faced stone

Stone on which the face has been broken to an approximate plane.

Spot or Spotfixing

The mortar applied to the back of dimension stone veneer to bridge the space between a stone panel and the backup wall. Used to plumb a wall.

Stacked Bond

Stone that is cut to one dimension and installed with unbroken vertical and horizontal joints running the entire length and height of the veneered area.

Sustainable Slip Resistance

An Accelerated Wear Test (AWT) is used to measure Sustainable Slip Resistance. This test simulates the long-term wear and changes in slip resistance, and takes into account the life-cycle performance of materials together with the associated aspects of abrasion resistance and cleanability, as a component of wider durability studies. Sustainable Slip Resistance tests are recommended for high traffic floors with high maintenance regimes.

Tactile Indicators

Tactile indicators are particularly designed to assist the vision impaired, but are also used as an added safety precaution to all pedestrians. There a two types of tactile indicators, hazard and directional. Hazard tactile indicators have raised dots warning of a change of direction or impending danger. Directional tactile indicators have raised strips informing of the safe direction to follow. Tactile indicators must meet the 30% luminance contrast required in AS/NZS 1428.4 and a ‘W’ pendulum slip resistance required by AS/NZS 4586 Ramp Test.

Tessellated Tiles

Precisely calibrated floor tiles that have been extensively used in the UK and Australia, but have their origins in France. Typically the body of the tile is compact and vitrified, boasting porosity values of 3 per cent or lower. Tile patterns frequently feature geometric motifs. However, vast potential exists for creation of unique designs.

Terracotta

Traditional clay used to produce unglazed, cream to red body tiles, generally extruded and 12 mm thick or more. Surface may be rustic, smooth, polished, or waxed. From the Italian word meaning baked earth, terracotta is a form of hard-baked pottery tile which is used either in its natural red-brown colour, or painted, or with a baked glaze. Terracotta has been used architecturally since the 7th Century BC. In modern practice terracotta is manufactured from carefully selected clays, which, combined with water and vitrifying ingredients, are put through a pug mill or other device to reduce the mass to homogeneity. In cakes of convenient size the clay passes to the moulding room. In the case of repetitive pieces such as tiles the clay is pressed into plaster moulds to form a shell. The moulded pieces are finished by hand and then are ready for baking in a kiln or reverberatory furnace.

Terrazzo

A faux-marble flooring system, originally created by Venetian construction workers as a kind of 15th century value-added product. The workers used marble chips from upscale jobs to create Terrazzo. The workers would usually set them in clay to surface the patios around their living quarters. Consisting originally of marble chips, clay, goat milk (as the sealer), production of Terrazzo became much easier after the 1920s and the introduction of electric industrial grinders and other power equipment. Modern terrazzo is made with synthetic resins like epoxy or urethane.

Texture

Surface quality of stone independent of colour.

Textured Finish

A rough surface finish.

Thermal Shock Resistance

Ceramic tile’s ability to resist alteration when subjected to rapidly fluctuating extreme temperatures.

Tolerance

Dimensional allowance in the fabrication process.

Translucence

The ability of many lighter-coloured marbles to transmit light.

Travertine

A form of massive calcium carbonate, CaCO3, resulting from deposition by springs or rivers. It is often beautifully coloured and banded as a result of the presence of iron compounds or other (e.g., organic) impurities. This material is variously known as calc-sinter and calcareous tufa and (when used for decorative purposes) as onyx marble, Mexican onyx, and Egyptian or Oriental alabaster. Travertine is generally less coarse-grained and takes a higher polish than stalactite and stalagmite, which are similar in chemical composition and origin.

Tread Tiles

Trim tiles for stairs featuring a ridged or abrasive strip to prevent slipping; can be overhanging or abutted. Also known as Step-nose tiles (also Step-Tread).

Trim Tiles

Tiles of various shapes designed to meet the specific architectural or sanitary needs of a given installation. (See bullnose, caps, coves, skirting, mitered tiles, etc. also known as Special trims)

Tumbled finish

A weathered, gaining finished created when the stone is tumbled with sand, pebble or steel bearings.

Unglazed Tiles

Tiles which may be left untreated after firing. Unglazed tiles derive their colour and texture from their raw materials or may be coloured by means of oxides dispersed throughout the body.

Vein

A layer, seam or narrow irregular body of mineral material different from the surrounding formation.

Vein Cut

Cutting quarried marble or stone perpendicular to the natural bedding plane.

Vitrified Tiles

(See Porcelain Stoneware)

Wall Tiles

Generally glazed, non-vitreous tiles, for use on walls where mechanical strength and impact or abrasion resistance are not considerations.

Warpage

Dimensional defect of a tile's surface flatness; condition where one corner of a tile is not in the same plane as the other three.

Wastage

Generally add 10 per cent to the amount required for wastage due to cutting etc. If the installation is complicated or a lot of cutting is involved, the amount for wastage may need to be increased to 15 per cent.

Water Absorption

The quantity of water a tile can absorb expressed as a percent of the dry tile weight. High water absorption corresponds to a porous structure, while compact, vitrified structures feature low water absorption.

Water Proofing

Preparing a surface to be protected from exposure to water, usually by installing a pan or waterproof membrane.

Wear

The removal of material or impairment of surface finishing through fiction or impact use.

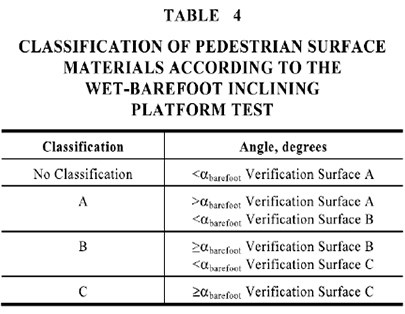

Wet Barefoot Inclining Platform test

Pedestrian surfacing products intended for applications, which become wet during normal usage and are subject to barefoot traffic, may be classified by the wet-barefoot inclining platform test method. Barefoot test operators walk down (forward) and up (backwards) the test surface on the platform using half steps. During the test there is a continuous regulated flow of water (with wetting agent) on the test surface. The operator controls the gradual increase in platform angle. The wet-barefoot inclining platform test classifies surfaces by the specific angle at which slip occurs on the material under controlled laboratory conditions. The measurement and reporting of this angle provides a means of classification, and is not a suggestion that the material is safe to walk on at the slope reported in the test results. Pedestrian surfaces should not be installed at the angles reported in this test.

There are a number of Australian testing laboratories with the necessary testing apparatus, thus enabling the laboratory verification of an overseas classification, if required. Wet-barefoot inclining platform tests performed overseas may be deemed compatible with AS 4586—2013, in the appropriate circumstances and with appropriate quality assurance.

The above information should not be relied upon without reference to Australian Standards SA HB 198:2014. Information and tables sourced from Australian Standards SA HB 198:2014.